3Ĭell culture process development starts with cell line generation and selection, followed by process and media optimization in small scale systems, including 96-well plates, shaker flasks, and bench-scale bioreactors, for high throughput screening purposes. Today, the combination of high titers and large capacity has gradually shifted the focus of cell culture process development from pursing even higher titers to controlling product quality and process consistency at all development stages and production scales. The enhancement of specific productivity per cell is achieved not only by selection of highly productive clones, but also by optimization of medium composition and bioreactor operation conditions. After two decades of intensive development work in cell line, media and bioreactor condition optimization, cell specific productivity of over 20 pg/cell/day can be routinely achieved for production cell lines 1 high titers up to ∼10 g/L and cell densities of over 20 million cells/mL in fed-batch processes have been recently reported by a few companies at major conferences. In terms of manufacturability and scalability, mammalian cells have historically been considered difficult to work with due to factors such as low yield, medium complexity, serum requirement, and shear sensitivity, although the latter has generally been incorrectly overemphasized. In response to the strong demand, many companies have built large scale manufacturing plants containing multiple 10,000 L or larger cell culture bioreactors. Since antibody therapies may require large doses over a long period of time, manufacturing capacity becomes an issue because the drug substance must be produced in large quantities with cost and time efficiency to meet clinical requirements and pave the way toward commercialization. For antibody manufacturing process development, maintaining desired quality attributes while reducing time to market, maintaining cost effectiveness, and providing manufacturing flexibility are key issues in today's competitive market, where several companies are often working on therapies for similar targets and clinical indications. With the increasing number of protein therapeutic candidates, especially monoclonal antibodies (mAbs) entering various stages of development, biopharmaceutical companies are increasingly looking at innovative solutions to deliver this pipeline. We also summarize the current thinking on appropriate process development strategies and process advances that might affect process development. This review provides an overview of the state-of-the art technology in key aspects of cell culture, e.g., generation of highly productive cell lines and optimization of cell culture process conditions. Successful implementation also requires appropriate strategies for process development, scale-up and process characterization and validation that enable robust operation and ensure compliance with current regulations.

The robust implementation of this technology requires optimization of a number of variables, including (1) cell lines capable of synthesizing the required molecules at high productivities that ensure low operating cost (2) culture media and bioreactor culture conditions that achieve both the requisite productivity and meet product quality specifications (3) appropriate on-line and off-line sensors capable of providing information that enhances process control and (4) good understanding of culture performance at different scales to ensure smooth scale-up. A range of biotherapeutics are currently synthesized using cell culture methods in large scale manufacturing facilities that produce products for both commercial use and clinical studies.

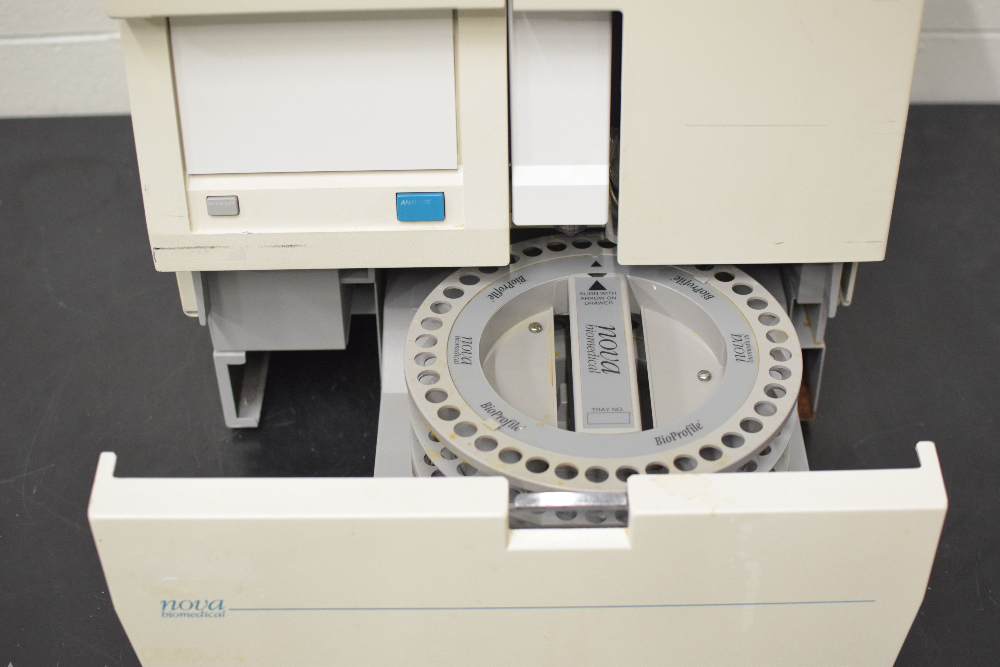

Nova’s BioProfile Analyzer is a fully automated, multi-test systems designed for rapid, simultaneous analysis of 10 key nutrients, metabolites, and gases in cell culture and fermentation processes.Animal cell culture technology has advanced significantly over the last few decades and is now generally considered a reliable, robust and relatively mature technology.

0 kommentar(er)

0 kommentar(er)